The new Transatlantic Secret Weapon for BCD 2015!

Here’s an interesting new-build story on the development of a BCD Bf109T. It’s from Max Uttien, a regular Carrier flyer in continental competitions, and occasionally a visitor to some UK events (the Nats last year for one). Max and I collaborated on getting the Eric Conley Profile class Bf109T plan into the site library (have a look at how that happened in this site’s “Best of the US” section), and we have both committed to building one each to emulate (we hope!) the success that this model has had in the USA. Max corresponded with Eric Conley, and also with another contact in Holland who specialises in laser and milled rib-sets, and Flyco (your correspondent); here’s some extracts so you can see how things developed. I’ve used Google translate to turn elegant German into adequate English!

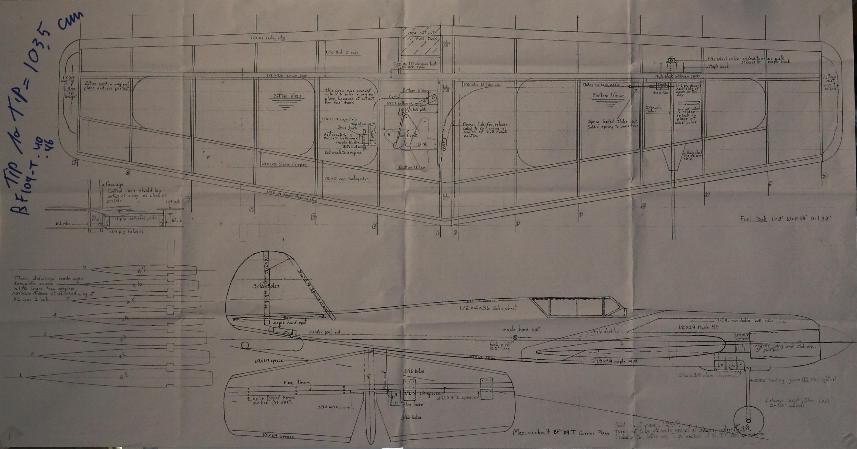

First, the plan (you can download the full-sized plan, courtesy of Eric Conley, its designer):

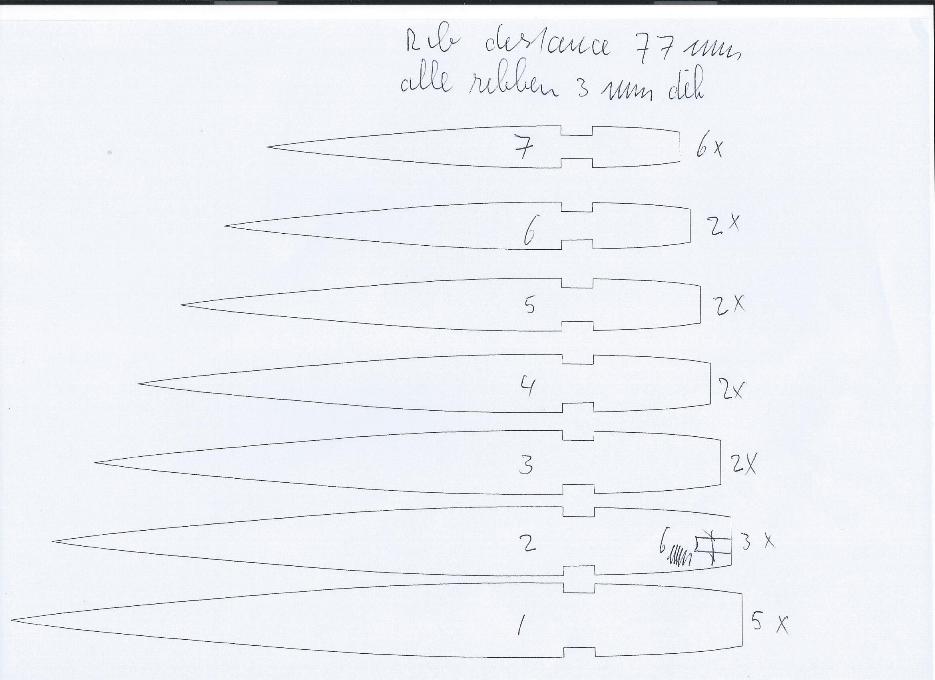

Max extracted the ribs from the plan and sent them to his contact who has the equipment to cut them by machine, either by milling or laser-cutting.Here they are:

There were some queries from the guy doing the machining…

Two questions: – Rib Number 2 you will have 3 times according to your sketch.Why So? Can all ribs of be made of 3mm – we make two for the tip and the middle which you glue against each other. The middle and tip ribs are then 2×3 = 6mm.The advantage is that all can fit on one sheet and everything can be machined with a 1mm cutter. This gives very beautiful corners.

Max replied

Rib 2 – 3 pieces – because of the heavy engine I need a piece of the wing in order to countersink the tank.

(Some time then passed, then Max received an email from his machinist with an update…)

Sorry it took so long. Milling made no progress, so the the ribs will be done by laser cutting, a bit more expensive but I‘m pretty proud of them. The slots are a bit thicker +- 0.2 mm. This is because the laser is +– 0.2mm wide.

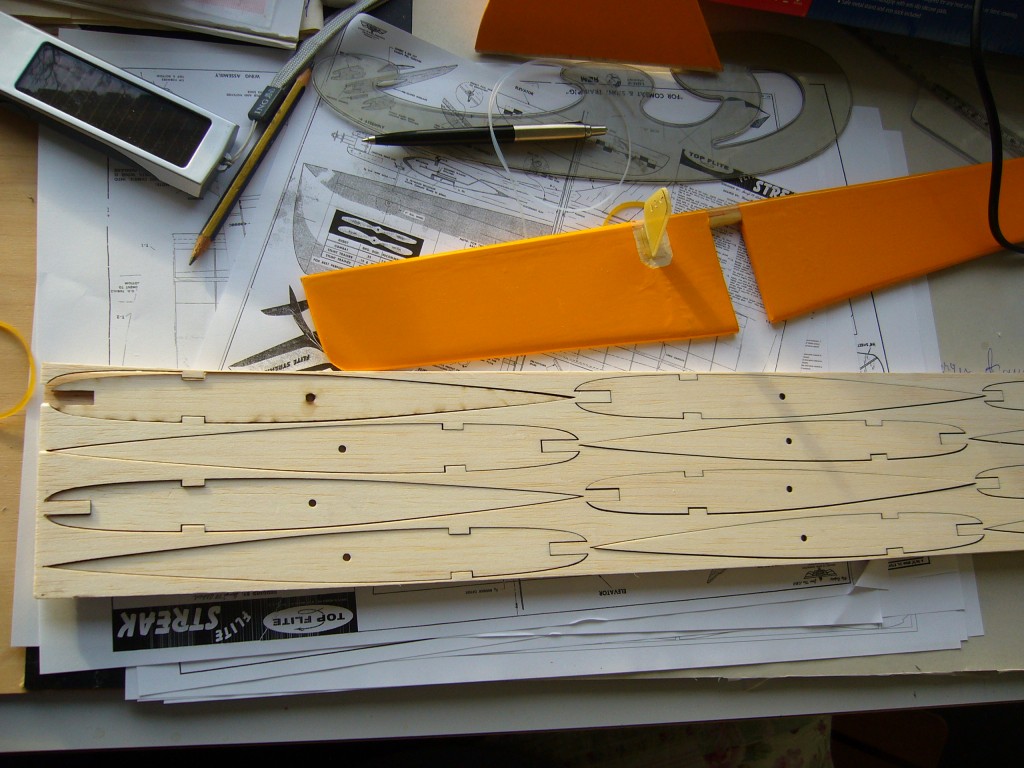

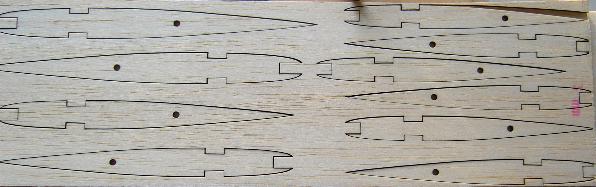

So Max now had a set of ribs to do the prototype build. Eric’s plans are unusual as the wing is designed to be built upside down. and the plans are drawn that way too. Max suggested that I wait until he’d de-bugged the build and the friend had made any necessary changes to productionise the ribsets. He then reported progress to me, a few weeks later:

Max to Flyco

On the prototype set of wingribs the main spars are set under an angle towards the nose of the wing, that means that it is difficult to build a straight wing the way Eric does, I will have a look at it this week and let you know. Maybe a thin wing is not that good for BCD? Maybe a thin wing works better for Class 1. The width crankcase of the Jett .40 is 35 mm, that is also the thickness of the wing off the model. I did a dry fit of the rib set; If you built the wing symmetrical, using the front spar and the 3 mm alignment holes, or build the wing as Eric does; with the upside of the wing flat against the building board. The main spars fit beautifully.

Max was then ready to send me my set of ribs, and very generously offered to let me have them for free as it had all taken some time – thank you Max – I wasn’t going to complain! Soon after, the box arrived in the UK, and I was very impressed.

By now, Max had finished his first Bf109T. Why is this such a special model that we both wanted to build one? Well, it’s the current US record holder for profile Carrier, flown by Burt Brokaw with a Nelson .36 at 99 mph on the fast 7, and 5 mph on the slow…there’s an article on this site giving more info on the page “Eric Conley Plans”.

However, as Max said to me in an email this week, we can buy and build the best model. but there’s “…a single possible problem; we have to prove ourselves, in my case; where can I buy talent??” That applies to me too, Max!

Max sent some pix to Eric showing him what he’d built, and explaining the modifications he’s made to the 109 for the UK/EU BCD rules.

Max to Eric Conley:

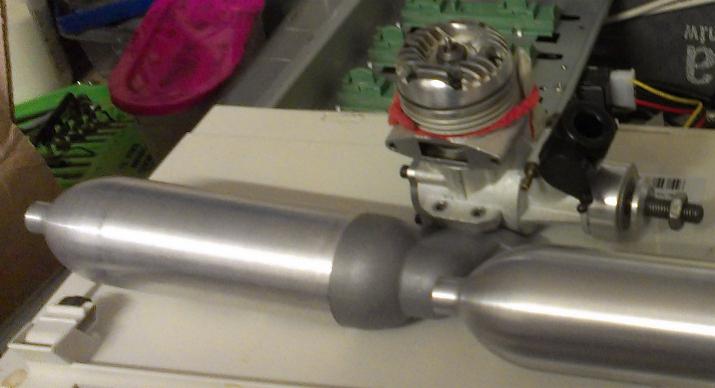

(I’m) …not even close to your building quality, but hopefully enough to get into the top half of the contest results. The gray model is roughly in accordance with your model, with the exception of the wing and the horizontal stabilizer, which are in line with the engine as we may only go up to 30 degrees in the hang. The wing thickness is somewhere between that of your model and my current models. Otherwise I have to do too much experimenting… New to me is a faster motor a Jett a .40 and throttle with a 2.4 Ghz throttle

Eric replied:

Eric Conley to Max

Always so nice to hear from you. The ribs look beautiful, I don’t think I could work with such well cut ribs. I’m now using 1/8 by 1/4″ spruce for my wing spars. Makes for slightly lighter plane and haven’t had a failure yet. I build a wing jig so I can get a better airfoil and although they are not perfect they are pretty close and satisfy me. I have built every wing I have since 1992 this way and don’t think I could build any other way now!

I really like your new plane and your choice of engines. My planes are designed to fly to the rules of AMA Carrier which means they will go fast and then go very slow because the wing quits flying and “just” becomes a giant air brake. So if you are going to not exceed 30 degrees your wing will do much better (my feelings). I sold one of my planes to Ron Duly and he could not adapt to the Nelson engine no matter what he did so he changed it out to a Jett .36 and he became a very happy camper. The Jett engine was not quite as fast as the Nelson but it was easy to use. The Jett engines are built to the highest quality

so will serve you well. I see you are using a remote high speed needle and you have fuel pressure from the quarter wave muffler, excellent.

So, that’s where we are as at mid-February 2015 – it’s going to be an interesting year!

If anyone fancies a Bf109T and some laser-cut ribs, the plan is free on this site, and for info about the ribsets, email flyco@carrier-deck.com and I’ll pass your questions on.